Yard Management System YMS: the intelligent solution for monitoring inbound and outbound vehicles and goods

With FasThink Yard Management System, efficiency, control and safety in the management and planning of vehicles and goods entering, parking and exiting yards

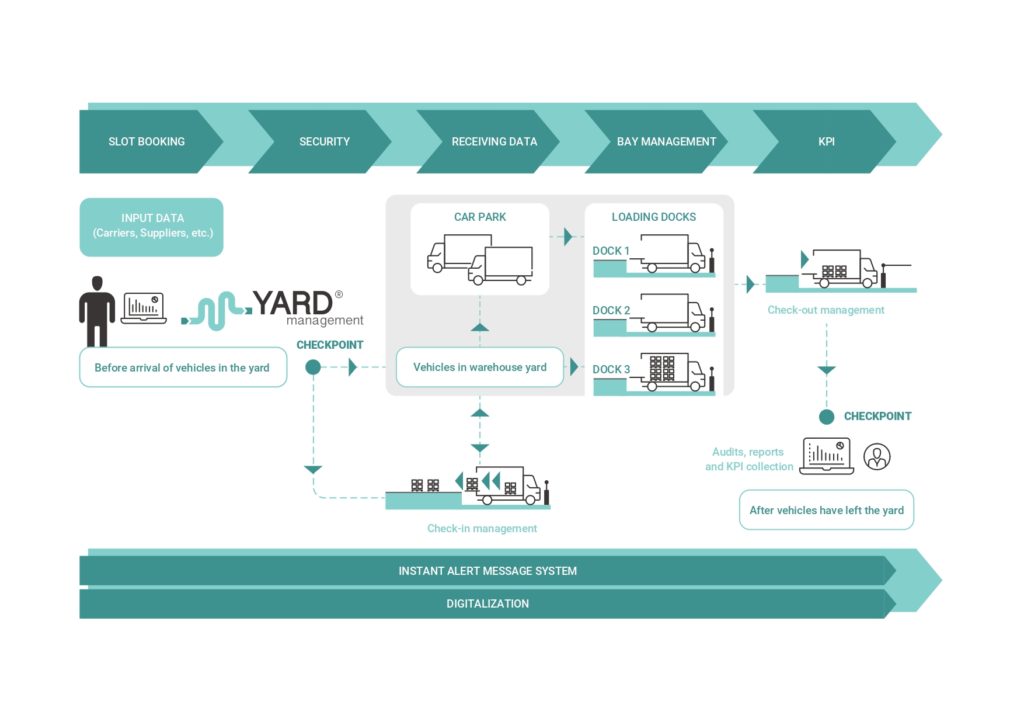

YMS is a transport management system used to monitor all vehicles entering and exiting warehouses or production units and digitally manage the loading and unloading operations of goods.

The System

YMS is developed on a web platform and structured to interface with management systems such as ERP, WMS, MES as well as interacting with field technologies such as cameras, identification and access control systems.

Yard Management, through its tools, allows you to manage specific tasks such as:

- Yard Booking: web portal dedicated to suppliers for booking transport

- Self Check-in: typically accessible from a totem positioned at the entrance which allows to independently manage all check-in operations

- Messaging: real-time communication system between internal and external users of the YMS platform

Modules & Functions

- SLOT BOOKING: for planning and optimizing arrival management

- SECURITY: for verification and authorization of vehicle access

- RECEIVING DATA: for the management of transport documents and to enable access to the unloading bays

- BAY MANAGEMENT: for the dynamic management and traceability of unloading / loading activities

- KPI: for generating reports on operational KPIs, waiting times, etc.

Thanks to integration with WMS warehouse management systems, with TMS transport systems, or with systems dedicated to fleet management, YMS is the ideal system to significantly increase efficiency, improve safety and reduce costs.

Advantages

- Reduce waiting and loading/unloading times

Estimated percentage reduction from 10% to 30%

Waiting times for loading and unloading can be drastically reduced thanks to more efficient planning. YMS allows you to manage the assignment of docks in an optimal way, avoiding queues and downtime for trucks, thus improving turnover times. - Optimize the use of resources and operating costs

Estimated percentage reduction of up to 20%

YMS allows optimized management of personnel and equipment, such as forklifts and vehicles for moving goods. This improvement in management results into a reduction in operating costs, thanks to the more efficient use of resources. - Decrease Error Rate and Associated Costs

Estimated percentage reduction from 10% to 15%

With a centralized system that controls every operation, you can reduce errors in vehicle movements, dock assignments and order management. Fewer errors means fewer costs related to delays and incorrect shipments. - Improve Warehouse Efficiency and Reduce Storage Costs

Estimated percentage reduction from 15% to 25%

Optimized flow management allows to improve the efficiency of storage areas and reduce goods storage times, thus helping to reduce costs related to warehouse space. - Increase Visibility and Real-Time Monitoring

Estimated percentage reduction variable but with a significant indirect impact

YMS provides real-time visibility, allowing companies to react promptly to any problems or changes, thus reducing wasted time and costs related to inefficiency. - Improve Vehicle Utilization and Savings in Transportation Costs

Estimated percentage reduction from 5% to 15%

More efficient planning allows to make better use of vehicles, reducing empty trips and optimizing routes. The result is a significant reduction in fuel and vehicle maintenance costs. - Reduce Total Cycle Times

Estimated percentage reduction of up to 30%

Optimized management reduces overall cycle time, accelerating operations and increasing the ability to handle more tasks with the same resources. - Save Labor Costs

Estimated percentage reduction from 10% to 20%

By automating and improving the coordination of operations, manpower requirements are reduced, with positive effects on overall personnel costs. - Sustainability

Implementing a YMS can play a crucial role in a company’s sustainability strategy, helping organizations achieve environmental goals. By optimizing the flow of vehicles within the yard, the system significantly reduces truck waiting times, which results into lower fuel consumption and, therefore, a significant decrease in CO2 emissions.